Laser Engraving Cutting Software User Manual----RDCAM V8.0

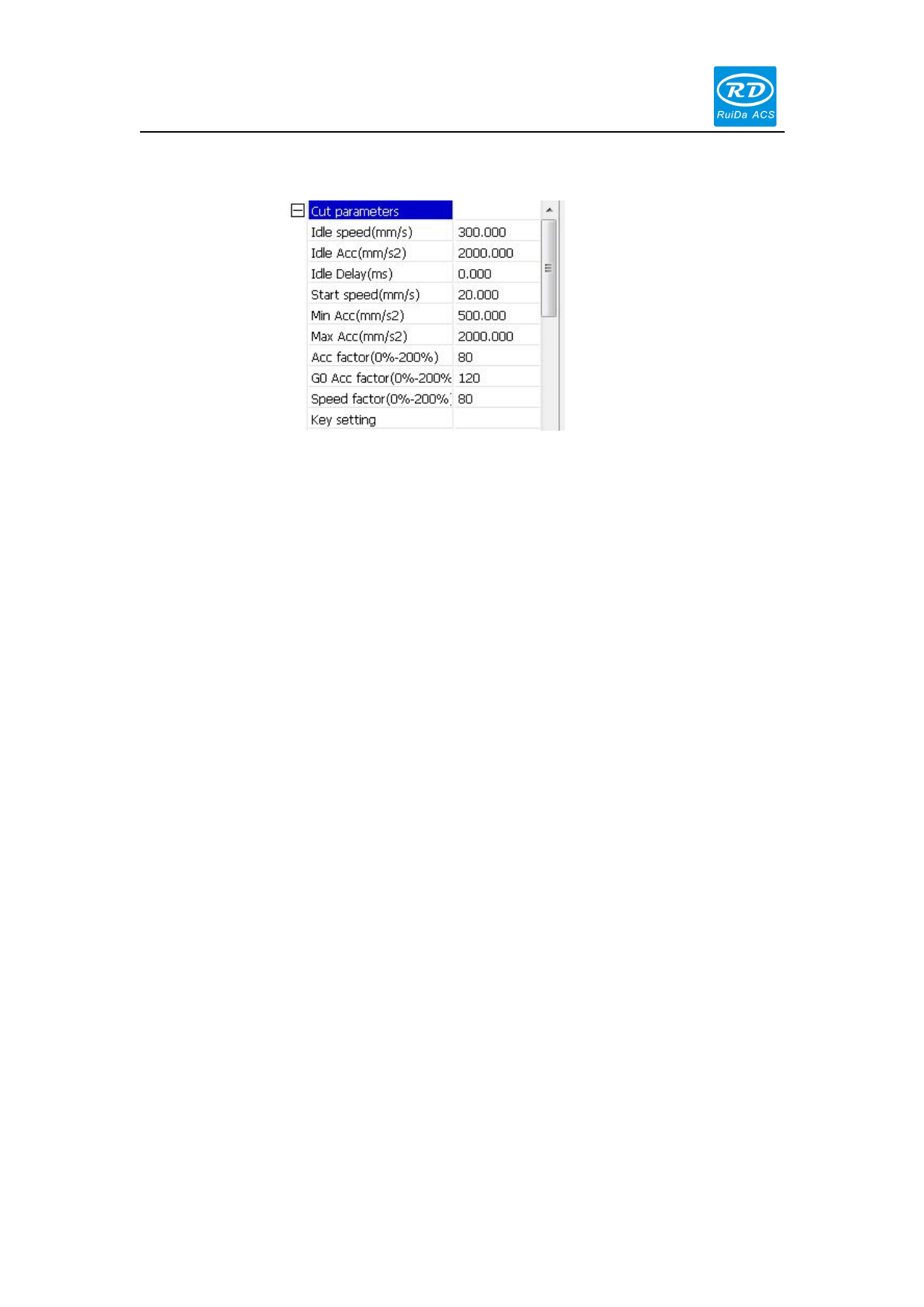

3.3.1 Cut parameters

Idle speed: this parameter decides the max. speed of all lines not emitting beams during the

operation of the machine. This parameter should not be lower than the lower of the jump-off speed

of the X-axis and Y-axis and not exceed the higher of the max. speed of the X-axis and Y-axis, if

the user setting is illegal, the controller will automatically take this parameter in the

above-mentioned rang; A higher idling speed can shorten the operation time of the entire figure,

while excessively higher idling speed may cause dithering of the tracks, therefore, you should take

all relevant factors into consideration when setting.

Idle Acc: The acceleration speed of idle walking, matching to the idle speed, if you set too slow,

the actual speed may not reach the setting value; if too fast, the mechanical structure may not

withstand and cause to dithering. Generally, the idle acceleration is a little bit higher than the

cutting acceleration.

Cutting Acc: the acceleration of cutting speed (cutting speed is the layer speed of the layer

parameters).

Acc factor: the coefficient of idle walking speed, the greater the ratio, the greater the idle speed.

Go Acc factor: the coefficient of cutting speed, the bigger the ratio, the greater the cutting speed.

Turning speed: the minimum speed at the turning corner in cutting process. You can reduce the

turning speed properly when processing the jagged material.

Turning Acc: it should match the turning speed.

Cutting mode: there are 3 kinds of cutting mode: precision cutting, fast cutting, ultra-fast cutting.

The user can choose it according to the actual applications.

Acc. mode: S-mode acceleration and T-mode acceleration. Generally, the S-mode acceleration is

more smoothly and T-mode acceleration is faster.

52 / 76

© 2016 Ruida Technology. All Rights Reserved.